[email protected]

+8613782744607

System type: Water Tube Steam Boiler for Textile Factory Boiler fuel: Soft coal, coal. System features: Environmental protection, fuel saving and a high degree of automation. Boiler application: Textile mills, knitting mills, spinning mills, etc.

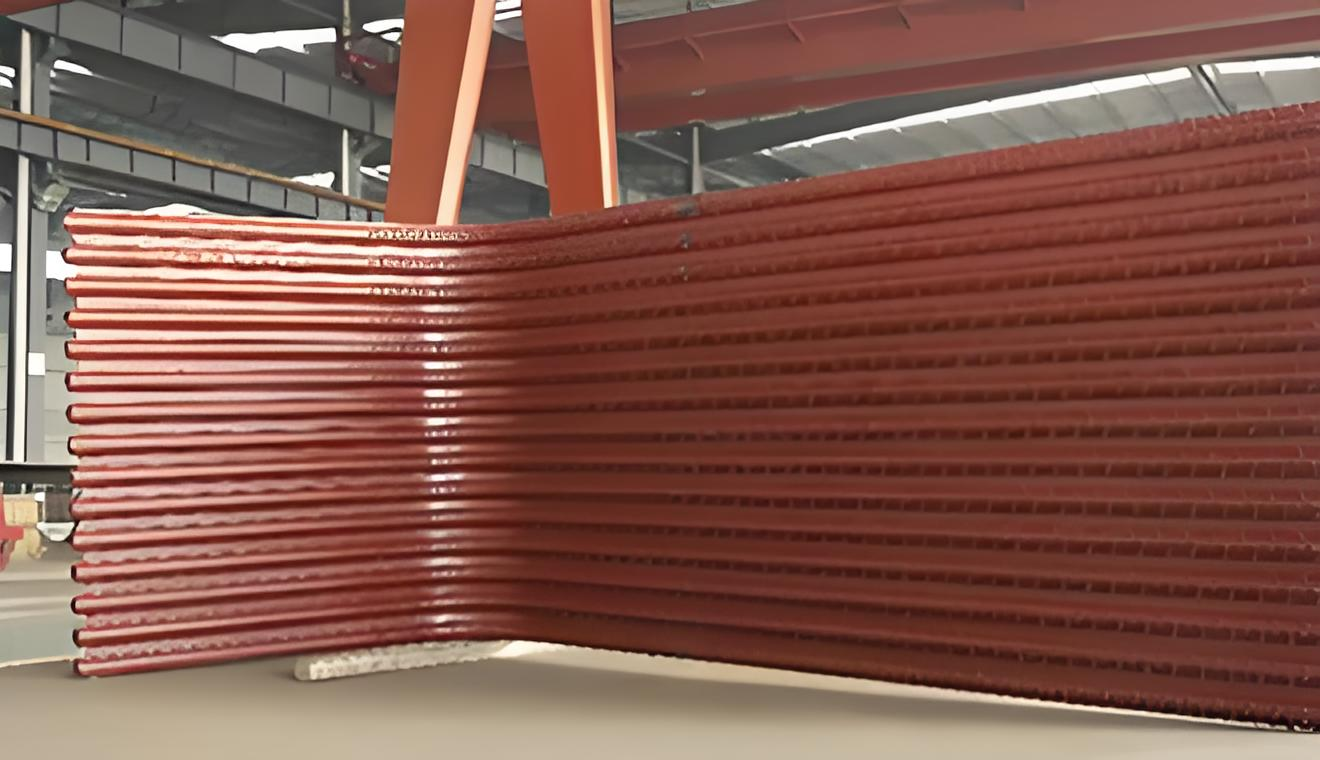

| Water Tube Steam Boiler SystemWe’ve optimized the AIX water tube steam boiler by refining the water wall and convection tube bundle, and redirecting flue gas into a vortex pattern for enhanced heat exchange. This design boosts steam production with less fuel, reducing operational costs while maintaining capacity. |

| Coal-Fired Combustion SystemAIX boilers incorporate a cutting-edge combustion system to provide an efficient heat source. By optimizing the air duct and grate layout, we achieve a more balanced air-to-fuel ratio, promoting rapid and complete fuel combustion. Paired with an integrated dust removal system, this reduces suspended dust, nitrogen oxides, and sulfur oxides in the flue gas, ensuring your fuel is utilized to its fullest potential while minimizing environmental impact. |

| Fuel Supply for Textile IndustryAIX offers a customized fuel delivery system designed specifically for textile industry needs. This system ensures rapid and reliable fuel replenishment, maintaining a consistent steam generation rate. With its user-friendly design and seamless integration with the electric control system, the AIX fuel supply system simplifies boiler operation and management, enhancing efficiency and reliability. |

| Smart Control for Textile IndustryThe AIX water tube steam boiler control system is programmed to align with the unique demands of the textile industry. It adapts to user habits and operational conditions, continuously optimizing performance to suit your production processes. This intelligent system minimizes fuel consumption, helping you achieve significant cost savings while maintaining seamless integration with your textile factory’s operations. |

| Customized Steam Boiler valvesAIX boilers are meticulously designed and manufactured to meet the specific requirements of textile industry processes. The combustion and steam supply systems are tailored to align with your production needs, ensuring optimal performance. Constructed with premium materials, our boilers guarantee stability, safety, and reliability, providing a robust and secure system perfectly suited for your textile plant. |

Technical Parameters

We will recommend your Steam Boiler for Textile Factory Water Tube Coal Fired boiler system model according to your actual needs. Of course we can provide you with comprehensive technical support。

Item/Type | Steam Boiler for Textile Factory Water Tube Coal Fired | ||||||||

Rated capacity t/h | 4 | 6 | 8 | 10 | 12 | 15 | 20 | 25 | |

Rated steam pressure MPa | 1.25/1.6/2.5 | ||||||||

Rated steam temperature ℃ | 194/204/226 | ||||||||

Feed water temperature ℃ | 20 | 20 | 60 | 60 | 60 | 104 | 104 | 104 | |

Thermal efficiency % | 81.54 | 81.6 | 81.8 | 82.2 | 82.5 | 82.5 | 82.8 | 83.7 | |

Heating surface m2 | Boiler body | 99.68 | 155.5 | 181.63 | 233.6 | 298 | 316.7 | 456 | 625.3 |

Economizer | 69.76 | 140.6 | 183.1 | 209.3 | 209.3 | 225 | 242.4 | 267.8 | |

Fuel & consumption | Fuel type | Class II Soft Coal, Biomass, Wood Chips, Wood Pellets, | |||||||

Coal kg/h | 454.99 | 681.98 | 907.08 | 1128.34 | 1349.08 | 1686.35 | 2240.32 | 2770.29 | |

Biomass kg/h | 657.55 | 985.61 | 1310.93 | 1630.69 | 1949.71 | 2437.14 | 3237.74 | 4003.66 | |

Your experience on this site will be improved by allowing cookies.